I have not written anything for about my clogging battle with my Epson 4800 inkjet printer for several months because there has not been much to report, but after a pretty clog free period since Christmas 2008 I thought it was time to give an update…

Essentially I turned my printer off for a couple of months through November and December 2008, but as the New Year approached I wanted to print again. I did not expect it to work straight away as the reason for turning it off in early November was that nozzle clogs had appeared after a period of not running Harvey Head Cleaner regularly due to pressure of work etc.

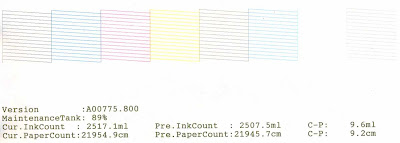

Sure enough several colours were missing and I ran through the gamut of clog recovery techniques, but was not getting too far quickly enough so I took a deep breath and ran a Power Clean cycle – the first time I ever have as I have always been advised to avoid them if at all possible. I then immediately ran a second Power Clean cycle quite by accident – I meant to tell it to run a nozzle check and hit the wrong button on the printer’s control panel…I desperately tried to stop it by turning off the printer, rebooting the computer etc but nothing deterred it; it just simply carried on from where it had got to in its cycle. I was not at all happy as the two cycles used 308ml of ink between them…

When I did eventually run a nozzle check all was OK except that the maintenance tank now needed changing (which I did using the technique I posted earlier – [here]) and the Light Magenta (LM) was completely missing. I ran a couple of prints and still it was missing, but the cartridge was nearly empty so I put in afresh one, ran a single cleaning cycle and all was perfect – not a single line missing in any of the nozzle check patterns.

Since then all has pretty much been sweetness and light!

Since the New year I have been religiously following my clog free method of printing a nozzle check once a day using Harvey Head Cleaner; print a full spectrum print either via Autoprint or a real photo at least every third day; all the while keeping the printer sealed in a all encompassing cover with a damp sponge inside the paper tray to keep the humidity inside the printer above 40% - for most of this year it has hovered around the 45% mark. Full details of my anti clogging regime can be found – [here].

I have had a single bout of colour channel loss – this was the Photo Black (PK) channel. Essentially running daily auto nozzle checks I had not noticed that there had been a paper jam and nothing had printed for a few days; this combined with the sponge drying out leading to lower humidity caused the problem. The paper had not fed because the tray holding the sponge had slipped down into the paper tray impeding the paper loading mechanism – to stop that happening again I put in a blob of Blu Tack (which is easily removable if need be) into the compartment to stop the tray sliding down.

A couple of weeks later PK disappeared again and this time the printer monitor was indicating that PK was running low, so I changed it. It immediately came back and there has been no problem again.

During all this time the printer was taking it upon itself to run its “auto something or other” cycle every week or so – each time using up about 9.5ml of ink; all to no purpose as far as I can see – see [here] for my previous observations and frustrations on this bit of the 4800’s story.

Conclusions

The power cleaning cycle seems to have cleared out the system admirably. This followed by my anti-clogging regime has kept the system working fine except when the regimen went wrong and when a cartridge had nearly run out. Which does rather reinforce my observations over the last couple of years that the most likely colour to give a problem is the one with the lowest ink levels in its cartridge – making me think that there is still something about ink levels and cartridge pressure to sort out… Read more...