About six weeks ago I was despairing that my Epson 4800 inkjet printer would ever be reliable again and that it would forever more be clogging/losing ink channels.

This may be premature and stupid, but thanks to the advice from lots of people (an example of mass collaboration?), mostly on the Yahoo 4000/4800 forum, I think that I have pretty much resolved the problem (now that is a really stupid thing to say…) – here’s how.

If you want to know the sort of frustration I have had with this printer over the last six months then clicking the “Nozzle Clogging” label will show you, most specifically – this posting.

In a previous posting I said that I was going to try someone else’s solution – here are the details. At the time I was not that confident that it would work simply because I had tried the “print often” approach to try to keep the printer happy; and it had not worked for long. Anyway I tried it and it initially did work, but after about a week the printer went back to its bad old ways and I went through a particularly traumatic weekend trying to coax it back into health, which I managed very early on the Monday morning, just in time to go to my day job. Being a bit sceptical that the new regime would work I did not use a cover because I could not find one, although I did use a wet sponge inside the printer cover; but I had been trying that for sometime anyway.

I decided to redouble my efforts.

That was six weeks ago – since then I have tried a few more things, learnt quite a lot, but most importantly I have only suffered from 5 clogs/ink channel losses, all involving the LM ink and twice the LK as well. In nearly all the cases this happened after an "auto something or other" happened - it sounded awfully like an automated cleaning cycle, but I have turned that function off, so I am completely in the dark as to what is actually happening when this happens and why.

In the first four cases only one simple nozzle clean brought back the nozzle check to perfect, with no repeated clean/rest/puddle clean cycles – the fifth, and most recent, took a full set of clean/rest/puddle clean cycles to clear, but I think I know why...

This is what I think is the reason for the worst case of clogging happening – Initially I bought a cheap interim solution (see cover posting here) and then bought a bespoke cover for the 4800 in anti-static vinyl on eBay. I used the cheap one for a couple of weeks and when the bespoke one arrived I put it on. I had stopped monitoring the humidity inside the printer by then. I restarted it when I had the problem and was very surprised to see that the humidity inside the printer head had dropped to about 40% – clearly, given my recent experience, this is on the borderline.

The bespoke cover fits better, but is not as long, leaving a gap around the bottom of the printer; does not have an apron to wrap around the under the paper tray (which is actually the transparent zip around top of the cheap storage bag/cover I tried – see photo below) and has a big gap at the back to allow access to the roll paper cover etc. All this means that there are plenty of gaps for the humidity to escape from the machine with the proper cover; much less so with the cheap interim one. I have now reverted to the cheap one and the humidity has climbed back to 50+% again. Leaving the under wrapper undone causes the humidity at the print head to reduce by 5-10% points (e.g. 55% to 48% humidity) – I guess, because humid air is heavier than dryer air, it simply falls out the bottom of the printer…

So effectively the printer has been available to print whenever I wanted it to except for one day.

So what have I done?

Below is the recipe for what currently works for me.

The recipe comes in three parts:

- General set up and printer configuration

- Printer exercise routine

- Materials and techniques to have to hand

1. General set up and printer configuration

First – USE A COVER… an all enveloping cover, for the reasons described above – see photo below with the apron tucked under the paper tray.

I believe that this was the single most important thing I did. The cover is not to keep the printer clean, although that is not a bad idea in itself, but to keep the humidity inside the printer up. In a previous post I reported on what I found it did for the humidity, but essentially I found that combined with a wet sponge it keeps the humidity inside the printer at about 50%. I believe that keeping the humidity up is the key to a happy (not-clogging much) printer.

Place a wet sponge in a tray in the paper tray – see photo below – the aim is to provide a source of humidity inside the printer. I find that I need to refresh the sponge about once a week.

Be careful not to put too deep a tray in the paper tray. The paper lifting mechanism lifts across the whole paper tray width and if the sponge tray is too deep it will be pushed into the rod (arrowed in the photo above) and cause miss-feeds.

I also now permanently monitor the humidity inside the cover by placing a wireless remote sensor out of the way of the print head carriage to the far left of the printing area - see photo below. This sensor tends to read about 10% points below the sensor near the sponge in the paper tray (e.g. paper tray humidity reads 60%, inside the cover it reads 50%). If you do this be careful not to impede the print head movement at all, or you will hear a nasty and probably expensive crunching sound!

Turn off the auto nozzle check and cleaning function on the printer – this only seems to cause clogs. See my earlier posting about why and how to do this.

Turn off the auto paper size checking function – See my earlier posting about why and how to do this, but suffice to say that you will be using plain paper in the printer as part of the print “little and often” routine. I have found that this tends to cause the printer to stall as its sensitivity to correct paper size seems to be greater than the size tolerance on plain paper.

2. Printer exercise routine

Fill the paper tray with plain paper – I have found 100gsm paper to feed more reliably than normal cheap 80gsm copier paper.

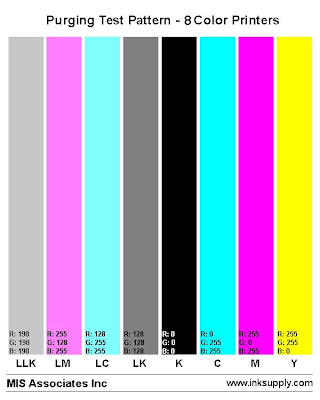

Download and install the free utility MIS Autoprint (see here for instructions on how) and choose a purge file that exercises all the ink channels (here is why). Also make sure that you have “Print Preview” turned off in the printer set up, as that will stall the process as well. In my set up this uses about 0.6ml of ink a time, or 1.2ml a week.

Buy a copy of Harvey Head Cleaner – unless you are willing and able to print nozzle checks manually every morning and evening. Harvey makes sure that, by running a small amount of ink through all the ink channels by printing a nozzle check, you exercise the whole print head regularly. I have set Harvey to print twice a day at 7.00am and 7.00pm; I have also set it to run if I turn the computer on within 24 hours of the last scheduled run time – circled in red in the screen shot below. This makes sure that you automatically run a nozzle check even if you turn your computer on after the scheduled time.

The printer reports using 0.1-0.2ml of ink per nozzle check, although this seems high compared with 0.6ml for a full page of colour for the Autoprint output. In any case it uses around 2ml of ink a week, which is about the equivalent of 1-2 A4 prints, or 1/50th of the ink to clear a bad clogging problem.

The combined Autoprint and Harvey ink usage over a year would be around 180ml of ink if you religiously stuck to the regime, although even over a month I have only really managed to do 90% of it. This equates to a couple of major cleaning bouts – only you can tell whether the time and frustration vs. routine ink wastage equation works for you.

I am pretty sure that I can reduce the actual number of nozzle checks and Autoprints, but don’t want to tempt fate just yet. As you can see in the screen shot above you can also tell Harvey to "Skip check if printer used within xx hours".

For me the reduction in frustration and the increased availability of the printer to print when I want it to are well worth the effort, even if it is something that Epson should be ashamed of…

(If you think that this is wasteful of paper I put the nozzle check paper back into the paper tray so that I get 4 checks per sheet…).

3. Materials and techniques to have to hand

Learn how to do a “Puddle Clean” – my method is posted here.

Become aware of the head cleaning protocols that have built up as “lore” for Epson printers. This effectively amounts to:

- Do not use Auto nozzle check – it often just moves the problem around

- Only run two consecutive nozzle cleans before running a full page print of some sort

- It is often wise to let the printer rest for an hour or so if a couple of nozzle cleaning cycles and full page print have not cleared the problem

- For major clogging/ink channel losses use puddle cleaning

Buy some “Fixyourownprinter” head cleaning solution – I have found it is very effective in clearing clogs; more so than distilled water.

Useful things to have at hand are:

- A small torch/flashlight

- A 20ml syringe with plastic extension (Kwill filling tube)

- Distilled water

- Lint free wipes – Pec Pads, the same ones I use for sensor cleaning on my DSLRs - I use these wrapped around a stick instead of cotton buds which might leave strands of cotton around to upset the print head etc

- A sense of humour

- …and one final requirement: patience!

So if I have one piece of advice it is – KEEP THE HUMIDITY UP AT AROUND 50% – all the rest helps but does not do enough if the humidity drops significantly below 40%.

Now all I have to work out is what the "auto something or other" is and how to stop it and why the LM channel is always the first one affected – any ideas?

Good luck – please let me know if you have any suggestions, refinements or comments to make.

Just one more thing - I have no commercial connection with any of the companies producing any of the products or services mentioned in this blog, other than as a happy customer. Read more...